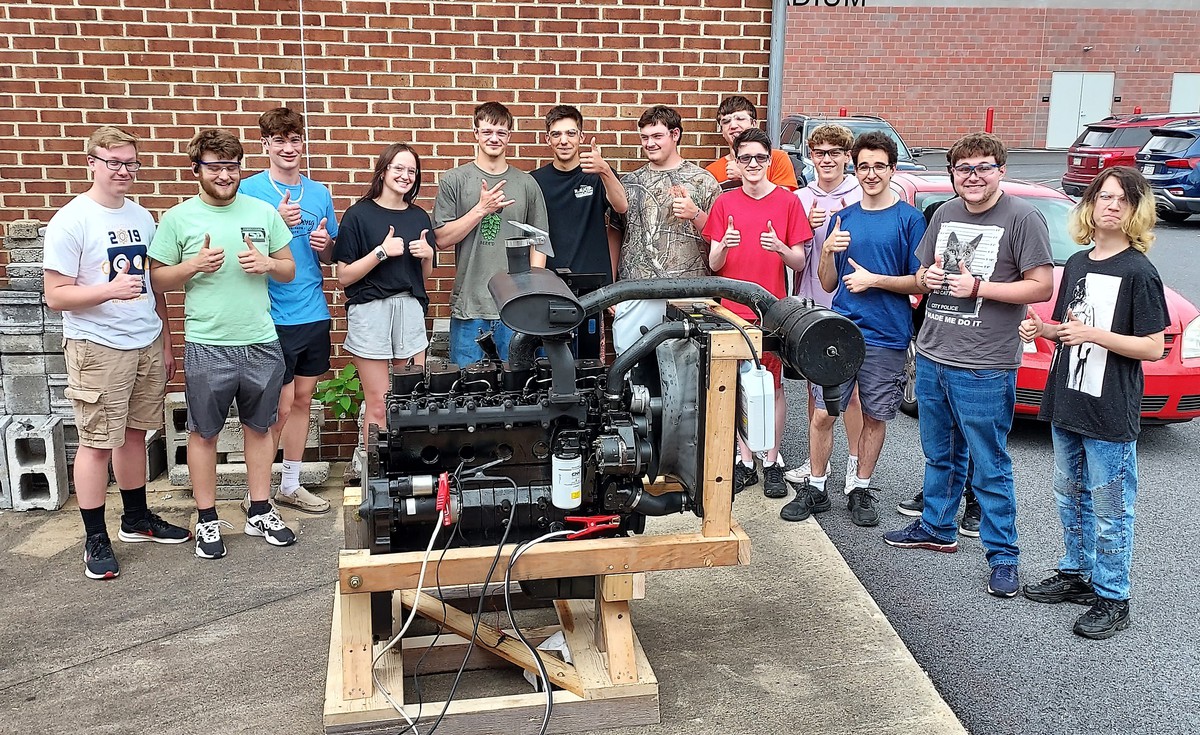

Boyertown High School's Diesel Engine Project

When we heard about an upcoming diesel engine rebuild project at nearby Boyertown High School, we were happy to play just a small part. Check out the full story below, as written by Andrew Schopf!

Diesel Engine Project Revs Up for BASH Students

Written by Andrew Schopf, Technology and Engineering Department at BASH and Freshman Academy TSA Advisor

The Tech R&D: Engineering class here at BASH was able to start the diesel engine that they have been working on all year. The students were very excited to see it run. This project began in 2019 but was hindered by COVID in 2020 and the lack of in-person learners in 2021. That means that this year's class had to finish something that was started three years ago without access to any of the previous students for advice or answers to questions. Here is an overview of the project:

Initially, the students were tasked with finding a used engine, making it run and reliable, and then repurposing it into an electric generator or mobile power unit within the school year.

Due to covid, the 2019-2020 class had the engine about 50% dismantled when school was shut down and could never put it back together. That class was primarily senior students.

The 2020-2021 class only had two in-person learners who worked very hard to organize the parts from the previous class and install what they were able with minimal resources.

This year's 2021-2022 class was tasked with reassembling the engine, designing and building a mobile stand for the engine, and ultimately making it run. It was quite an undertaking considering these students were freshmen and sophomores and were not in the class when the project began. They designed the parts for the stand using SolidWorks 3D Modeling software and then used the welders and plasma cutters purchased by the Foundation for Boyertown Education to weld them together. The wooden pieces were cut and assembled with tools and equipment also purchased by the Foundation and the memorial gift donated in memory of Charles "Roy" Herb.

Reinstalling the parts from the previous classes was a very tedious process, but our students persevered and were ultimately successful.

All the used engine parts were cleaned and inspected, sand-blasted and painted, then reinstalled on the engine.

Many parts were donated by Wengers of Myerstown and Martin Stone Quarries.

The engine is a Cummins 12 valve diesel and was originally installed in a 1991 Case International 5130 tractor.

This project is the embodiment of problem-solving and practical application. These students worked very hard, and I am proud of their work ethic, perseverance, and accomplishments.

Thank you to everyone who made this project a success! #BEARProud